It’s frustrating to spend countless hours designing a document or packaging only to discover that your printer has the audacity to print the wrong colors. The issue is not necessarily with your design. The problem is that not all printers use the same information or interpret data in the same way.

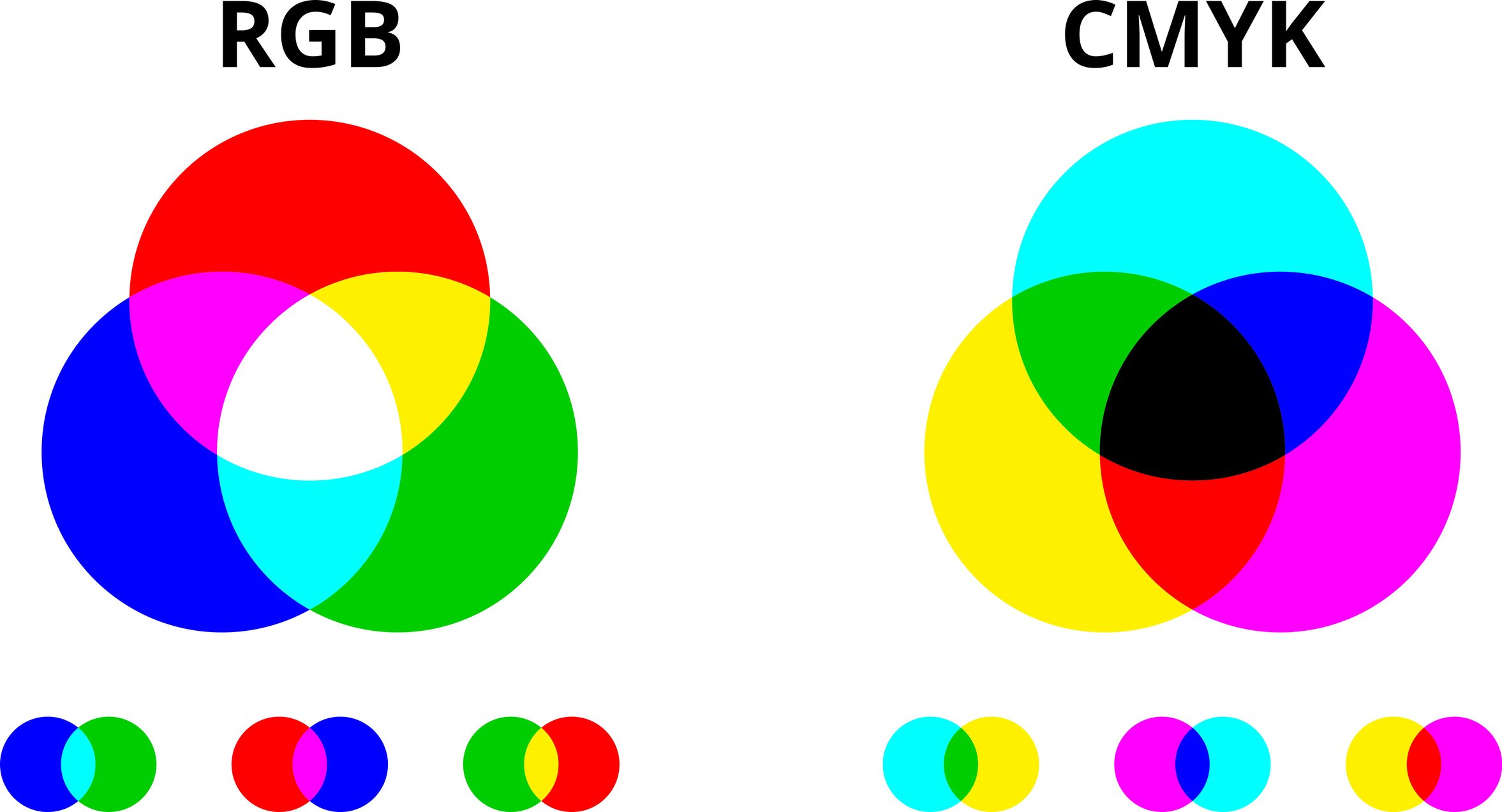

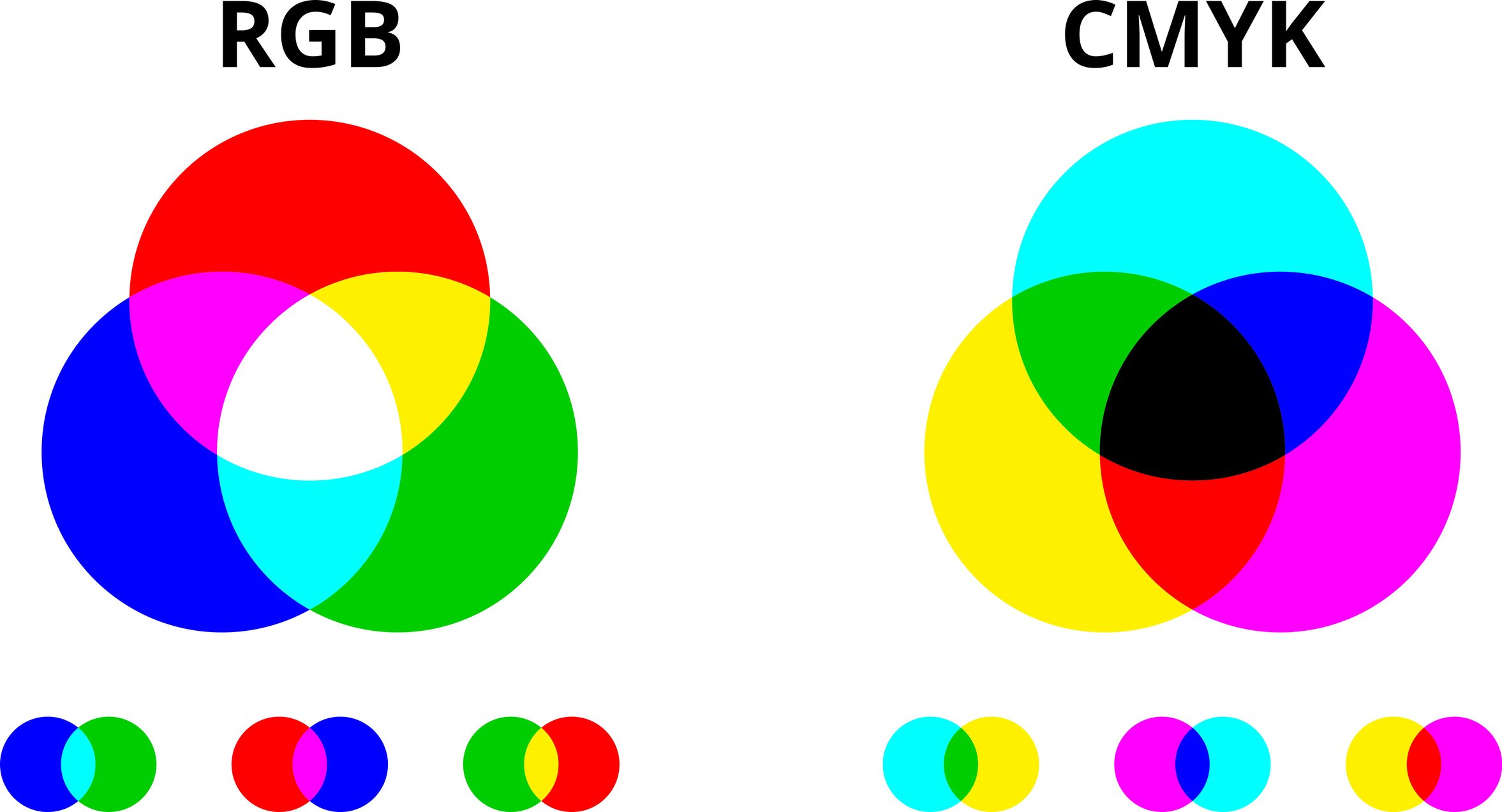

The best way to define colors is to use numbers associated with various pigments. Numbers don’t lie to us because the number values don’t change. Instead of recognizing red, green and blue (RGB) values often used on computer screens, high-end digital printers use a CMYK color wheel consisting of cyan, magenta, yellow and key (black). In both processes, colors combine to print dark colors that may appear as black ink.

These variances make a big difference and result in different secondary and tertiary colors. To recap:

What is RGB?

RGB is a three-color process that stands for red, green and blue – the primary colors. These colors of light are used in combination, to display color for digital designs (e.g., web pages, TV, etc.)

What is CMYK?

CMYK is a four-color process and stands for cyan, magenta, yellow and key (black). These colors are preferred for use on printed materials because it helps achieve a true color.

Here, we’ll take a closer look at why printers don’t all print the same and what you can do to get the best color output possible.

Printer Colors vs. Computer Screen Colors

First, let’s consider that in a typical software program like Microsoft® Word, the specific colors you choose are represented by the RGB system which is intended for viewing on a computer screen, not a printed page or on products. Now, imagine you invented a product that contains both plastic and metal components, and both materials need to be bright red. You found a manufacturer who can build your product, however, you want both the plastic and metal to be the same, exact red color you specify.

With so many shades of red available, how are you going to do it?

The good news is that you can specify the color of your product based on the CIE Chromaticity Diagram, also known as the LAB color space. In this diagram, all colors in the same location in this color space look the same to a standard observer.

on the CIE Chromaticity Diagram, also known as the LAB color space. In this diagram, all colors in the same location in this color space look the same to a standard observer.

The LAB color space is the Universal Translator for different devices and is more accurate than both RGB and CMYK. If you use LAB colors in your software program, such as Adobe® Photoshop, the colors may convert to CMYK or RGB when printed. Because your desktop program might use different starting values than your printer (RGB versus CMYK), the colors you expect to see on your printed document may be disappointing.

Get Blog Updates In Your Email

How to Achieve Accurate Printed Colors

If you print to an inexpensive deskjet printer from a big box store and I print the same document on a printer that costs thousands of dollars, you’d certainly hope to notice a marked difference in print quality and expect the higher-end printer to perform better.

And it would. That’s because most printers intended for higher-output business or commercial print jobs have the right translators to take the device information from the input source to the output source. Without the right color translation, however, even the most capable high-end printer will have problems.

Production print specialists often use printers and printing presses costing $100,000, $500,000 or even more. These specialized printers use a Color Management Module (CMM), a software that does the calculations to convert files from one color model (RGB) to another (CMYK).

Examples of CMMs include Adobe Color Engine (ACE), Heidelberg CMM, Kodak CMM, Agfa CMM, and others. On a $100 deskjet printer, you have very little control over what the CMM is doing, but on the high-end printer, there is quite a bit of CMM control of input and output color space profiles.

Considerations When Designing Print Collateral

Taking a step back, consider what color space you work in when designing your document. You’ll likely work in the RGB color space. We can, on higher-end printing systems, set the raster image processor (RIP) for the color space profile based on your input source. That means we can set the RIP for RGB, but when your file is processed, it can keep the original color intent and translate it into the correct CMYK output profile.

Because of this, you will likely see a significant color difference between the desktop printer and the high-end printer. Once you tweak your formula to get exactly the results you need on the better printer and lock in your settings, you’ll get the color you want each and every time.

You may need to make some tweaks to get the print results you want. For example, calibrate your computer screen to the printer, which may require some assistance. It’s important to have realistic expectations from the onset and understand how the world of digital printing works as it relates to color management and color translations between different color spaces. Having a consistent color management system in place, whether it be big or small, will help you see the results you desire when printing in color.

Color Printing Tip: Converting RGB to CMYK

It is possible to choose CMYK or RGB for print projects. If you know in advance that your document is intended for a high-quality print job — say, brochures or flyers — explore the settings in the computer program you’re using to see whether you can change the RGB default color mode to CMYK prior to designing it.

Overcoming the differences between on-screen color and what ends up on the printed page is just one of the issues facing production print shops. Learn how to tackle other issues in our infographic, Overcoming the Top 5 Production Print Challenges.

The Gordon Flesch Company is the largest independent Canon dealer in the nation, as well as an authorized Ricoh Family Group (RFG) dealer partner. We’d love to show you how our print experts can help you manage the entire color space and achieve vibrant, consistent results. Reach out to us today for a no-cost, no-obligation assessment of your print production needs.

CMYK Printing vs. RGB: How to Print the Right Colors featured image">

CMYK Printing vs. RGB: How to Print the Right Colors featured image">

on the

on the